Today’s Electricity is one of the most useful sources of energy. Electricity is almost necessary in the modern world of a machinery, equipment or technologies. Electric power can be transmitted or distributed by over-headlines system or by underground cable system.

So underground cable prepared that it can withstand pressure and can be installed below the ground level and normally two or more conductors are placed in a single cable with separate insulation on each conductor.

Table of Contents

ToggleUnderground Cable necessary requirements

An underground cable must fulfil necessary requirements as follows:

1) Conductor used in underground cables should be tinned stranded because strands of cable gives more flexibility and carry more current and material used as copper or aluminum of high conductivity.

2) The cable must be provided with suitable mechanical protection so that it may withstand the mechanical injury.

3) The cable must have proper thickness and material of insulation to ensure the safety and reliability for the designed voltage.

4) The size of the conductor should be selected as per standard rating, so that the underground cable carries desired load current without overheating and damage.

Construction of Underground Cable

Que. State the function of layer in construction of a cable.

Que. Draw diagram of underground cable showing all the parts.

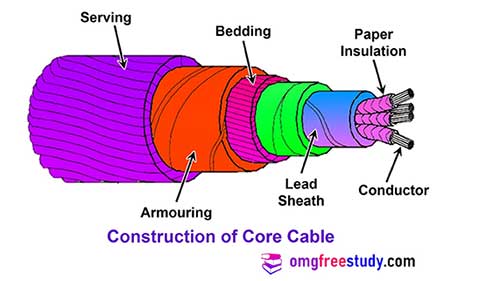

Figure shows the general construction of a core cable.

Cores or conductors:

A cable may have one or more than one core or conductor depending upon the type of service and construction.

The conductor used in cable should be tinned stranded. Strands of cable gives more flexibility and carry more current and material used as copper or aluminum of high conductivity.

Paper Insulation:

Each core of cable is provided with a suitable thickness of insulation, the thickness of layer depending upon the voltage level to be withstand by the cable.

The commonly used materials for insulation are rubber mineral compound, impregnated paper, varnished cambric or Petroleum jelly is applied to the layers of the cambric to prevent damage of underground cables.

Metallic sheath:

A metallic sheath of lead or lead alloy (aluminium) is provided over the paper insulation In order to protect the cable from moisture, gases or other damaging liquids like acids or alkalise present in the soil and atmosphere.

Bedding of U. G. cable:

After lead sheath, applied a layer of bedding which consists of a fibrous material like hessian tape or jute.

This layer protect the metallic sheath against corrosion and from mechanical injuries.

Armouring of underground cable:

Armouring is provided over the bedding, which is consists of one or more layers of galvanized steel wire or steel tape.

Its purpose is to protect the cable from mechanical injury while laying it and during the carelessness in handling.

Serving of underground cable:

In order to protect armouring from atmospheric conditions, a layer of fibrous material similar like bedding is provided over the armouring.

Download MCQ PDF on Underground Cable

Module 3: Wires, Joints, soldering, U.G. Cable

- Fundamental of electricity – conductors – insulators – wire size measurement- crimping.

- Wire joints – Types – Soldering methods.

- Under ground (UG) cables – construction – materials – types – joints – testing.

MCQ Questions PDF

This MCQ Question Is Taken From Bharat Skill Website Published By NIMI.

Objective questions on the above topics explain in video on YouTube.