A Brushless DC Motor (BLDC) is an electric motor. It work on DC voltage supply and controlled by using electronics circuit instead of brushes in conventional DC motors.

When semiconductor electronics were developed in 1960s, then the development of these motor are Possible. Now a days BLDC motor is more popular than the conventional DC motors.

Table of Contents

ToggleConstruction and working of BLDC

Que. With the help of necessary sketch, explain in brief the working of brushless DC motor.

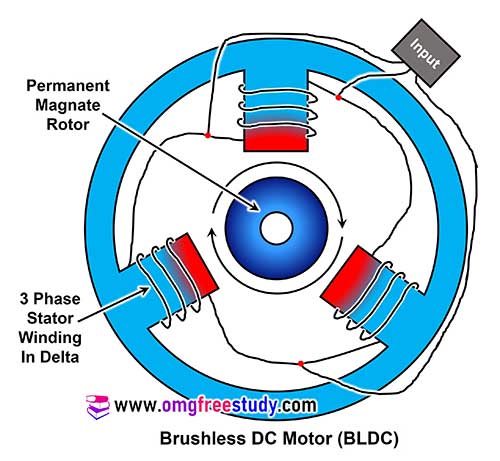

Figure shows the basic construction of brushless dc motor.

- The construction of BLDC motor is similar to that of permanent magnet synchronous motor.

- Inverter has to replace the mechanical inverter called as commutator of a DC motor.

- BLDC motor can be derive from a mechanically commutated DC motor with three armature slots. In armature winding connection of three phase winding is connected in delta.

- The commutator acts like a three phase frequency converter. Stator (excitation) and rotor (armature) change places.

- In BLDC motor commutation depends on the position of the rotor.

- The angle between the MMF (magneto-motive forces) of stator and rotor is fixed at 90 degree electrical.

- So the motor produces maximum torque and needs low reactive current it might be useful to advance commutation by few degrees to compensate the effects of the stray inductance and minimize reactive current.

- Speed can only be controlled by the motor voltage.

- The motor behaves like a DC motor, but in synchronous motor there are no problems with stability at any speed.

- Because of the PWM frequency inverter, variation of the motor voltage can be achieved easily by changing the duty cycle of the pulse width modulation. Suitable PWM techniques allow regenerative breaking, which increases dynamic and efficiency of the drive.

- Using best PWM techniques BLDC can operate smoothly with noiseless operation.

Advantages

- No mechanical commutator and brushes. Hence low maintenance and long life.

- Noiseless operation due to absence of brush.

- Can run at much higher speeds.

- Higher efficiency.

- Electronic control of speed and torque is possible.

Applications

Que. State any two application of brushless DC motor.

- Synthetic fiber drawing works.

- Turn table drives in record players.

- Spindle drives in hard disk circuits.

- Computer peripheral equipment’s as plotters.

- Gyroscope motors.

- Biomedical machines as heart pumps.

Watch MCQ Question Lecture on DC Motor and DC Gen. on YouTube by clicking here.