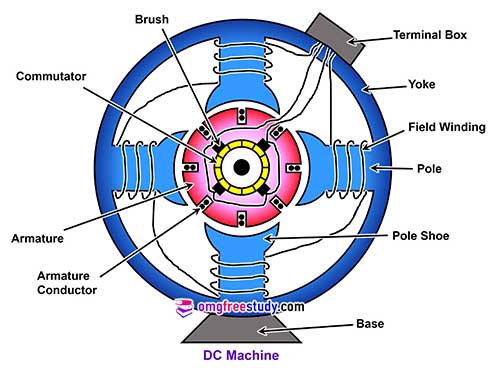

The constructional part of DC Machine are Yoke, Field winding, Pole, Pole Shoe, armature, commutator, brushes and gear etc.

Table of Contents

ToggleConstruction of DC Machine

Que. State the function and material used for part of DC generator or DC Motor.

Detail Construction and its parts of DC Machine are shown in figure below.

All parts of above dc machine explain one by one with its function and material used for making.

Yoke of DC Machine

- Yoke is also called as frame of the machine. It provides protection to the rotating and other parts of the machine from moisture, dust and mechanical damage etc. Also it provides the mechanical support for the poles.

- It is an iron body which provides the low reluctance path for the flux. This is essential to complete the magnetic circuit.

- Materials used for the yoke are basically the low reluctance materials such as cast iron, silicon steel, rolled steel, cast steel.

- It’s provides the mechanical support for the poles.

- For small dc machines the Yoke are made of cast iron. But for larger machines, cast steel or rolled steel is used.

Poles, Pole Shoe and Pole Core:

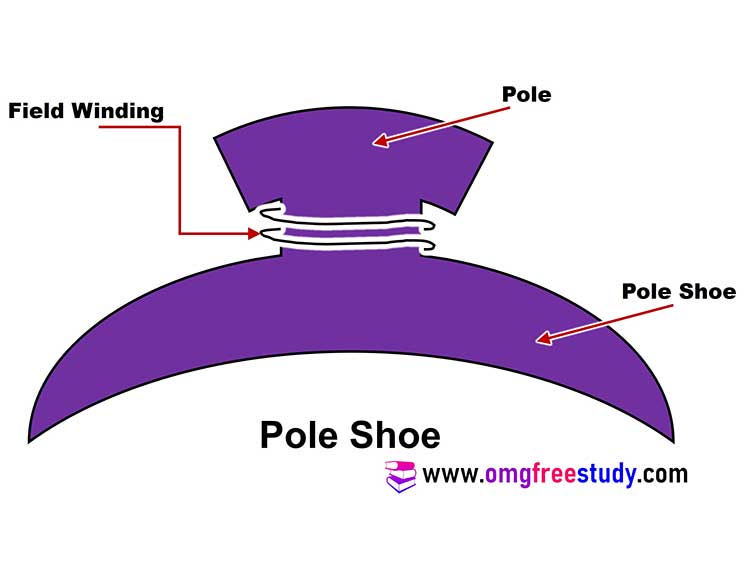

- The basic construction of pole and pole shoe is shown in fig.

- A pole of a dc machine is a supporting structure to electromagnet. The field winding is wound over the poles.

- Poles produce the magnetic flux when the field winding is excited by DC supply voltage.

- Pole shoe is an extended part or shower like structure of a pole. Due to its typical shape, it enlarges the area of the pole. Due to this enlarged area, more flux can spread and pass through the air gap to armature core and armature winding.

- for the construction of a pole or pole shoe low reluctance magnetic material such as cast steel or cast iron is used .

Field Winding of DC machine

- The coils wound around the pole cores are called as field coils.

- Series combination of field coils with each other to form the field winding of dc machine.

- Field winding is also called as Exciting winding, Because it produces the flux.

- Materials used for the field conductor is enameled copper.

Armature Core of Dc Machine

- Armature core is a cylindrical drum like structure which is mounted on the shaft.

- It is provided with a large number of slots all over its periphery, all these slots are parallel to the shaft axis, Armature conductors are placed in these slots.

- Armature core provides a low reluctance path to the flux produced by the field winding and this flux is cut by the armature conductor.

- The air holes are also provided in the armature core for the air circulation, which helps in cooling the armature core.

- Core constructed using laminations so as to minimize the eddy current loss.

Que. State functions of the armature core in DC machine and name material used for armature core.

Functions of armature core:

- Support the armature winding which is placed in its

- Rotate as a rotor with armature winding.

- Increase the permeance (ease of magnetization) of the magnetic path to increase the magnitude of induced EMF for a certain MMF created by the field

Material used for armature core:

High permeability, low reluctance materials such as cast steel or cast iron are used for the armature core.

Armature Winding of dc machine

Que. State the function of armature winding and name the material used for its construction.

The armature conductor is placed on the armature core slot to form an armature winding. And its conductors made of copper or aluminum wire.

Armature winding is connected to the external circuit (to load in case of generator) through the commutator and brushes.

Commutator of DC Machine

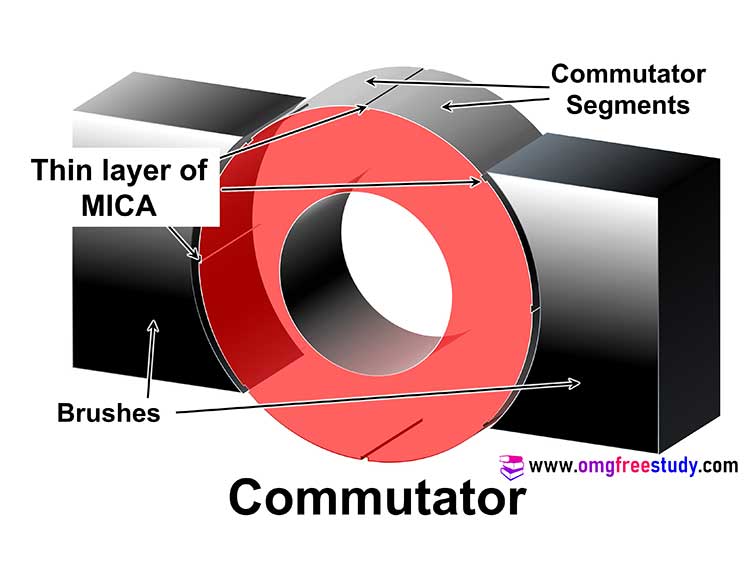

- A commutator is a cylindrical drum mounted on the shaft along with the armature core.

- It is made of a large number of wedge-shaped segments of hard-drawn copper.

- The segments are insulated from each other by thin layers of mica.

- Armature winding is tapped at various points and these tapping’s are successively connected to various segments of the commutator.

- For a dc generator it converts the alternating EMF generated internally into a DC voltage. So it basically works like a rectifier.

- It collects the current from the armature conductors and passes it to the external load via brushes.

Que. State the function of commutator in DC generator and name the material used for commutator.

Function of Commutator:

Commutator converts AC induced current in the armature winding into DC for external load.

Material:

- Commutator segments are made up of Copper.

- Commutator segments are insulated from each other by Mica.

Brushes

- Current is collected from the armature to the external load by the carbon brushes which are placed against the surface of commutator by small pressure using springs.

- It wear with time, hence they should be inspected regularly and replaced periodically.

- Brushes are made of carbon or graphite and shape like rectangular.

Shaft

- Shaft is a solid long rod like structure, which place by support of bearing in alignment for proper rotation. And it help to support and rotate rotor .

Que. State at least one function and the material used for the following parts of dc generator: (i) Yoke, (ii) Field winding, (iii) Commutator, (iv) Brushes

Part | Function | Material |

Yoke | Provides Mechanical support for Poles Acts as Protecting cover for Machine provides path for magnetic Flux | Cast Iron OR Cast Steel |

Field Winding | Produce uniform magnetic field in which armature rotates | Copper |

Commutator | Converts AC from armature to DC for generator Converts DC to AC for motor armature. | Copper segments insulated from each other by mica |

Brushes | To Collect current for generator & supply current in motors. | Carbon |

Watch MCQ Question Lecture on DC Motor and DC Gen. on YouTube by clicking here.