Purpose of using a line insulator in an overhead line is to hold the live conductor to prevent leakage of current from the conductor to the supporting pole. These are made of porcelain clay and are fully glazed to avoid the absorption of moisture from the atmosphere.

Table of Contents

ToggleProperties of Line Insulators

- High mechanical strength in order to bear conductor load, wind pressure etc.

- High electrical resistance of insulator material in order to avoid leakage currents to supporting structure.

- High relative permittivity of insulator material, so that dielectric strength is more.

- The insulator material should be non – porous, free from impurities and cracks else the permittivity will be lowered.

- High ratio of puncture strength to flash over.

For insulators of overhead line the most commonly used material is porcelain. But glass, steatite and special composition materials are also be used to a limited extent.

Types of Line Insulators

The following are the common types of line insulators in use.

- Pin type insulator

- Shackle insulator

- Suspension insulator

- Strain insulator

- Post insulator

- Stay insulator

- Disc insulator

Pin Insulators:

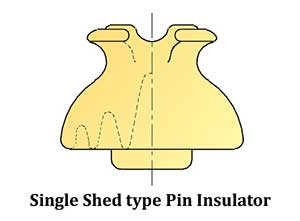

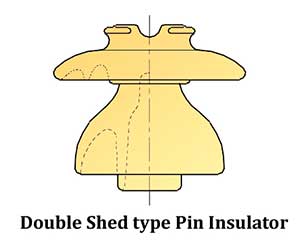

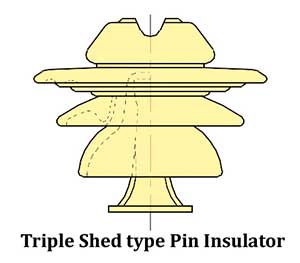

Pin insulators are used for holding the line conductors on straight running of poles in vertical position. Pin insulators are three types. i.e.

- Single shed

- Double shed and

- Triple shed

These sheds number are used to drip off the rain water.

Selection of sheds number or size is depend on voltage level.

For low to medium voltage lines Single -shed pin insulators are used.

And for over 3000V Double and triple shed pin insulators are used.

The pin type insulator is vertical in Shape, protected to the cross – arm and top of the pole. There is a groove on the top of the insulator for holding the conductor. The conductor is place in this groove and is bound by the galvanised wire of the same material as the conductor.

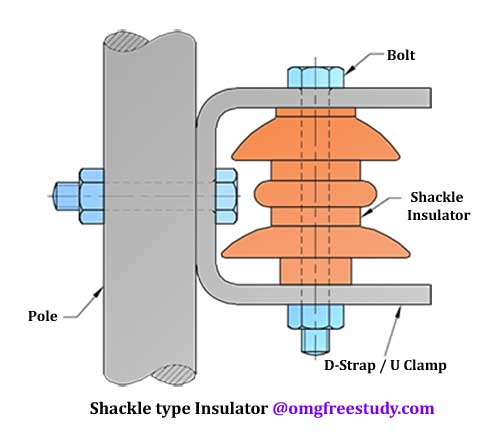

Shackle insulators:

Shackle insulators are generally used for terminating on corner poles. Usually these insulators are used for medium and low voltage distribution lines. Such insulators can be used either in horizontal position or in a vertical position. They can be directly fix to the pole with a bolt or to the cross arm. These insulators are clamped to the cross arms by one metal ‘U’ clamp with the help of bolts, nuts & washers.

Figure shows a shackle insulator fixed to the pole. The conductor in the groove is fixed with a soft binding wire.

Function of Shackle insulator is to reduce excessive tension on line. Also on supporting structure (pole).

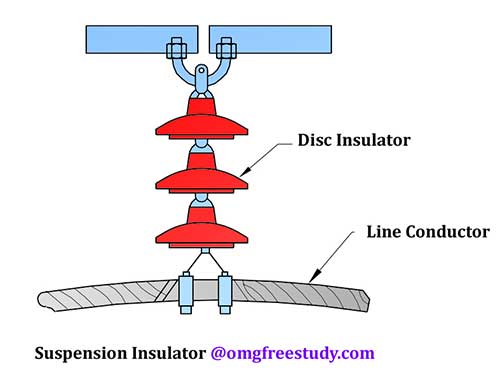

Suspension type insulators:

The pin type insulator is not economical beyond 33 KV because, cost of insulator increases rapidly as the working voltage is increased. Therefore For high voltage (beyond 33KV), it is a usually use suspension type insulators as shown in Figure. They consist of a number of porcelain discs connected in series by metal links in the form of a string. The conductor is suspended at the bottom end of this string. And the other end of the string is held to the cross- arm of the tower. Each unit or disc is designed for 11kv voltage. That means if the working voltage is 66KV, then six discs in series will be provided on the string.

Advantages of suspension insulator:

- They are cheaper than pin type insulators for voltage beyond 33 KV.

- 2 Depending upon the working voltage, the desired number of discs can be connected in series.

- 3 If any one disc is damaged, the whole string does not become useless because the damaged disc can be replaced.

- 4 The suspension arrangement provides greater flexibility to the line.

- 5 In case of increased demand on the transmission line, we can add the desired number of discs.

Strain insulators:

Strain type insulator consists of assemble of suspension insulator, which is used in horizontal direction for high voltage transmission lines. When there is a dead end or corner or sharp curve of the line were the strain insulator used. And also in order to relieve excessive tension of line, the strain insulators are used. For low voltage lines below 11KV shackle insulators are used as strain insulators.

Strain type insulator consists of assemble of suspension insulator used in horizontal direction.

Post insulators:

Such insulators can be used for mounting of buses, dropout fuses (DO), line conductors, Gang Operated Air Break (G.O.A.B) switches. These are of outdoor type and are available in 11kv, 22kv and 33KV ranges.

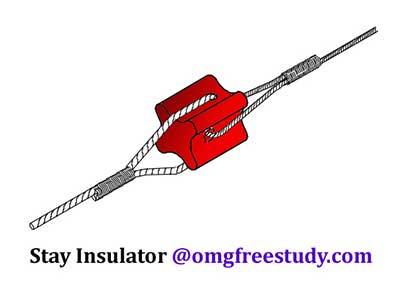

Stay insulators:

Stay insulators are also known as strain insulators and are commonly used up to 33 KV line.

These insulators should not be fixed below three meters from ground level. These insulators are also used where lines are stretched.

The supporting wire used in the opposite direction to the tension on the pole due to the overhead conductor is called ‘stay wire’.

This prevents the pole from bending due to the stress of the conductor.

These stay wires consist of 4 to 7 strands of GI wire.

The right size to use depends on the tension on the pole.

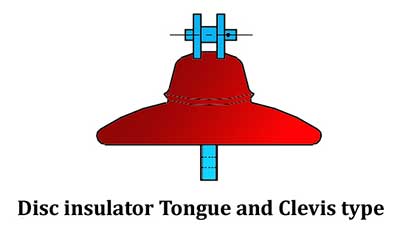

Disc insulators:

Disc insulators are made of glassy porcelain or hard glass and are used as insulators at dead ends, or on straight lines as suspension type for voltages 3.3 kV and above.

Disc line insulator are available in different designs:

Tongue and clevis type:

A round pin with a cotter pin is used to hold the tongue of one unit in the clevis of the other.

Ball and socket type:

In this case insulators are assembled by sliding the ball of one insulator from the side. A cotter pin is slipped in from the back of the socket so that the ball cannot slide out. These are used at dead ends.

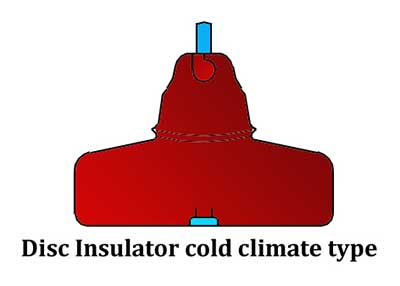

Insulators for cold climate:

For cold climate the depth of the lower cap is increased to get creep age distance which becomes necessary in cold climates. Two designs known as fog type and anti-fog types are available.

Assignment

Que. State and explain types of line insulators used in Transmission and distribution.

MCQ Questions PDF of Module 12 : Transmission & Distribution

- Electrical supply system – transmission – line insulators

- Line insulators

- Overhead lines /poles erection-fastening of insulator

- Joining of aluminium conductors

- Domestic service line – IE rules

- Bus-bar system – power tariff terms and definitions

- Power tariff – terms and definitions

Download MCQ Questions PDF of Transmission & Distribution