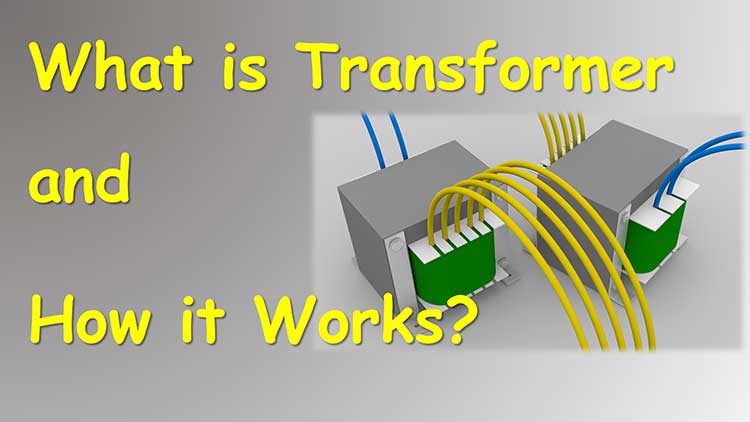

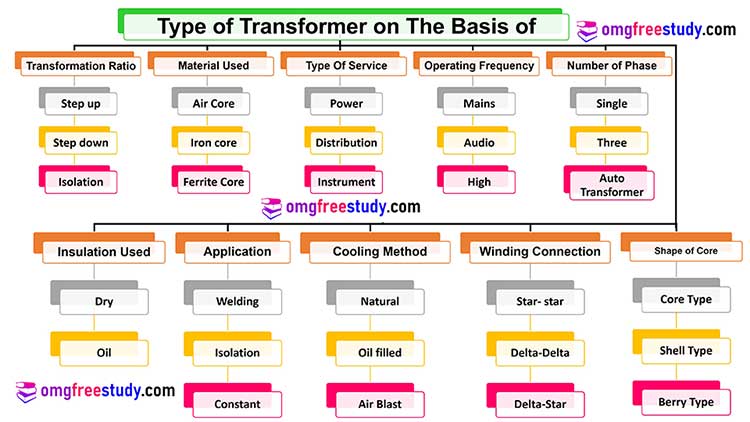

There are different types of transformer classified on the basis of shape of core, type of service, number of phase etc. It is used in the electrical power system for different application, like generation, transmission, distribution, utilization of electrical Energy and in small electronic application also.

Different types of transformer are Step up, Step down, isolation, core type, shell type, berry types, Instrument Xer, Single phase and three phase Xer, Auto transformer, Welding transformer etc. All types of transformer is shown bellow in tree diagram.

Table of Contents

ToggleBased on the Value of K

Types of Transformers Based on the Value of K (Transformation ratio) or Number of turns. Transformation ratio is defined as the ratio of secondary voltage to primary voltage of transformer. That is V2 / V1 and it is denoted by ‘K’.

Types are 1) Step up, 2) Step Down and 3) Isolation Transformer.

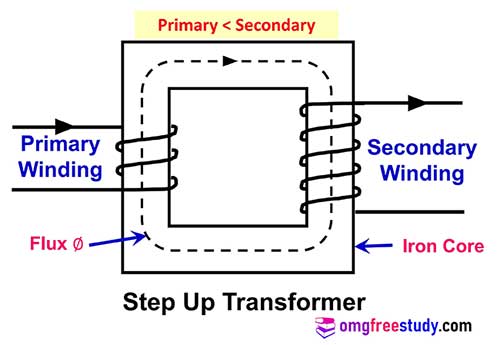

1.1. Step up transformer:

If the number of turns in primary winding is less than secondary winding turns then this type of transformer is called as step up transformer. OR

The transformer having value of K > 1, this type of transformer is called as the step up transformer. We get higher secondary voltage as compared to the primary winding, hence its name is step up.

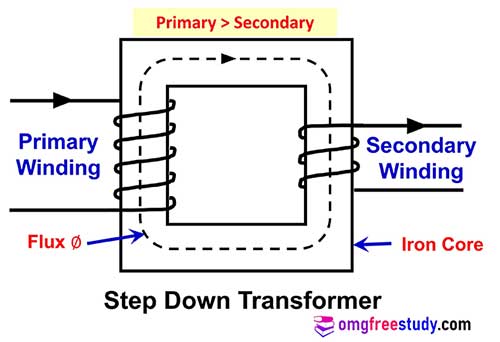

1.2. Step down transformer:

If the number of turns in primary winding is more than secondary winding turns then this type of transformer is called as step down transformer. OR

The transformer having value of K < 1 then it is called as the step down transformer. We get lower secondary voltage than the primary voltage, hence its name step down.1.2.

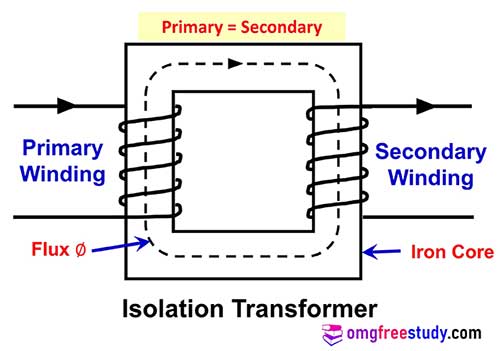

1.3. Isolation transformer

If the number of turns in primary winding is equal to the secondary winding turns then this type of transformer is called as isolation transformer. OR

The transformer having value of K = 1 then it is called as the isolation transformer. We get same secondary voltage as the primary voltage, hence its name isolation transformer.

On the basis of Shape of Core

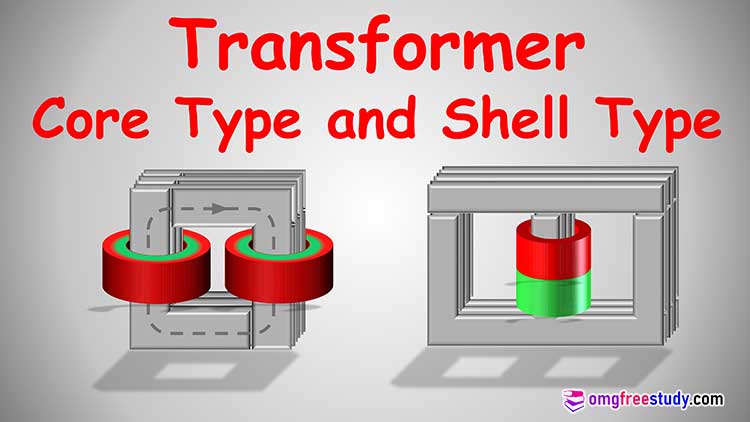

On Shape basis there are three type of transformer classified as follow, core type, shell type, berry type.

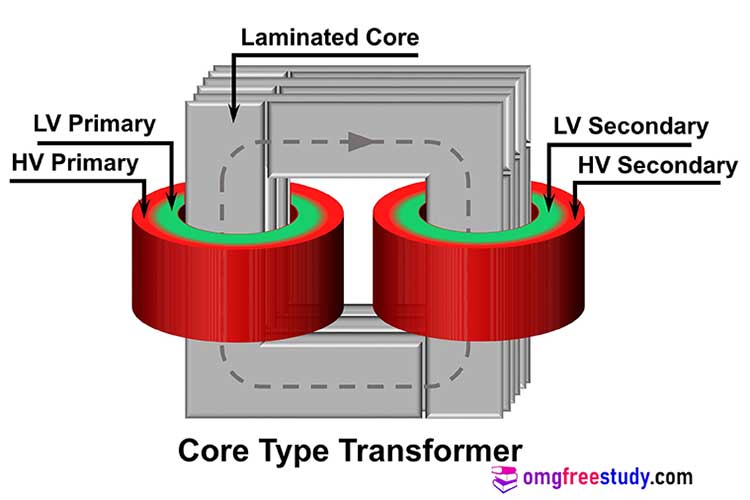

2.1 Core type

The structure of core of this transformer is in the form of a rectangular frame made from cold rolled grain oriented sheet steel (C.R.G.O.) with thin silicon steel laminations.

The primary and secondary windings are uniformly distributed on two adjacent limbs of the core. Both the windings are of cylindrical shape and they are arranged in a concentric manner the Low voltage (LV) winding is place near the core and high voltage (HV) winding is on over it.

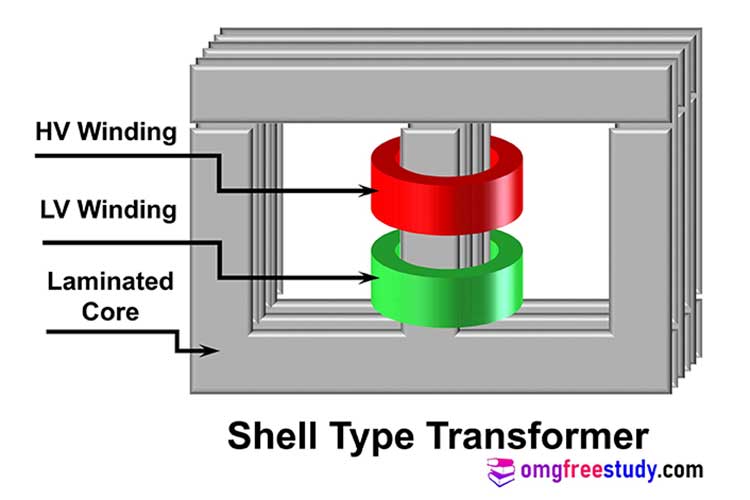

2.2. Shell type

The construction of a shell type transformer shown in figure. The primary and secondary windings are placed on the central limb of the core. The high voltage and low voltage windings are arrange in sandwich type.

This type of core provides double magnetic circuit and it provides a better mechanical support and protection for the windings. The material used for making core is same as core type transformer.

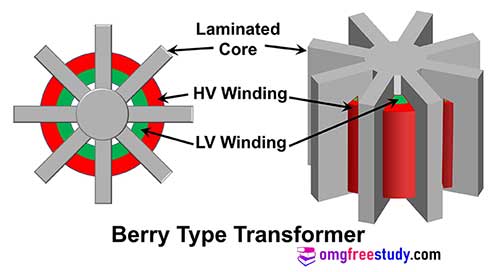

2.3. Berry type

It is basically a shell type transformer structure but the name is related to the design like berry and its cylindrical shape. Berry type transformer has distributed magnetic circuits and more than two independent magnetic circuits. The core construction of berry type transformer magnetic core and cylindrical windings is shown in graphics from top view and side view given below.

On the basis of Type of service

On Basis of type of service there are three type of transformer are 1) Power transformer, 2) Distribution Transformer, 3) Instrument Transformer .

3.1. Power Transformer

Usually power transformer is used in transmission line to transmit hug amount of power with high voltage ratings. Typically the voltage range of power transformer is about from 33KV to 400KV or more (400 kV, 200 kV, 110 kV, 66 kV, 33 kV) and power range is greater than 200MVA. So its size and weight is much more than all other type of transformers.

3.2. Distribution transformer

Distribution transformer is used in distribution networks to distribute power coming from transmission line. Highest range of the distribution transformer is 11KV and lowest one is 230V. It mean the variation of this type of transformer voltage rating depending upon the application where it use, this range is 11 kV, 6.6 kV, 3.3 kV, 440 V, 230 V.

3.3. Instrument transformer

To measure high voltage like 110 kV or 220 kV and high value of current, it is not possible from safety point of view to connect a voltmeter or ammeter to a very high voltage and current range line. Also an instrument which will stand to such a high range its size is very large comparatively normal range meters.

In such cases special type of transformers is required and this transformers called as instrument transformer. They are classified in two categories, current transformer and voltage or potential transformer.

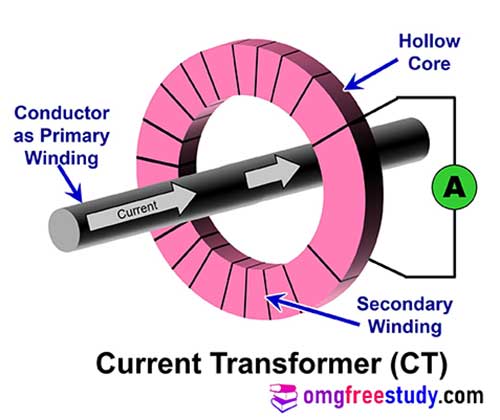

3.3.1. Current Transformer (CT)

If a large current carried by a conductor is to be measured, it is advice to avoid the direct connection of ammeter in this high current line, for this purpose a current transformer is used.

A current transformer (CT) is nothing but a coil wound on a core. The primary of C.T. carries the large current which is to be measured. The secondary winding is a low current winding, so the secondary of a C.T. is made up of large number of turns. The construction of a current transformer is shown in figure below.

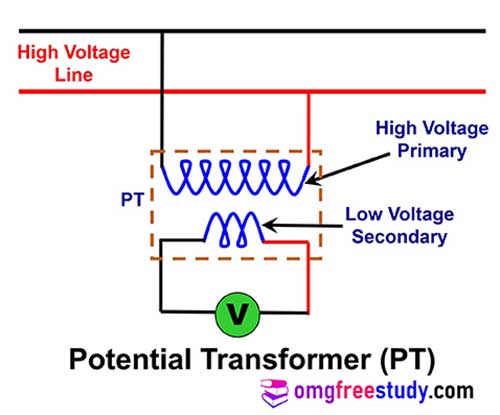

3.3.2. Potential Transformer (PT)

The potential transformer is second type of instrumentation transformer which is used to measure high ac voltage. The construction of a potential transformer is same as that of the normal transformer but difference is that potential transformer is always step down construction.

To measure high voltage, voltmeter is connected on low voltage side of transformer. The connection and construction of a potential transformer is shown in figure.

On the basis of Number of phase

On the basis of number of phase there are three types of transformer are as single phase, three phase and auto transformer.

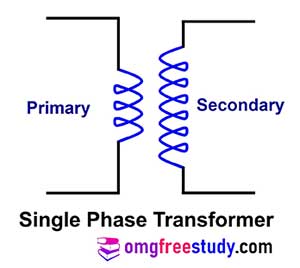

4.1. Single phase transformer

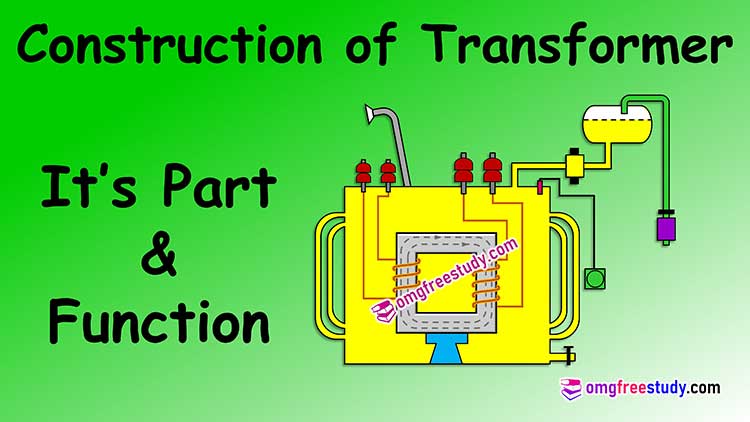

The basic construction of a single phase transformer is shown in figure. It consists of two highly inductive coils called as winding of transformer wound on a core made up of iron or steel material. Winding connected to the supply called as primary side and it connected to the load called as secondary side. In single phase transformer input is single phase and output is also same.

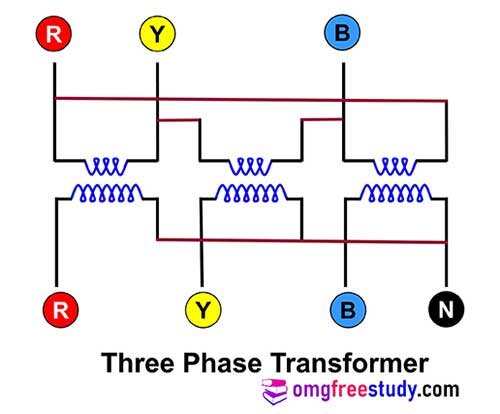

4.2. Three phase transformer

The three phase transformers constructed, by using three single phase transformers or three winding on core in single transformer tank as shown in figure below.

In three phase transformers, windings are connected such that the three primary windings are placed in delta or star and similarly the secondary windings are also connected in star or delta depending upon the application of area.

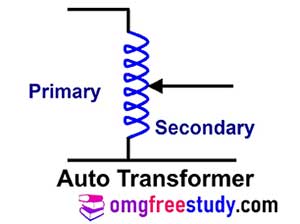

4.3. Auto transformer

It is a special transformer which may be single phase or three phase. In normal transformer has separate primary and secondary windings, but in the autotransformer some part of the windings is common for the primary and secondary windings. The basic construction of an autotransformer is shown in figure below.

It consists of only one or three winding wound on a core which is laminated and a rotary movable contact for selecting the particular portion of the winding. The autotransformer can used as a step down or step up transformer.

On the basis of Core Material used

5.1. Air Core Transformer

This type of transformer consist of a hollow nonmagnetic core like plastic or paper and primary and secondary winding wound over it. This type of transformer the transformation ratio is less than one. Air core transformer generally used in high frequency application because there is no iron loss in it.

5.2. Iron Core Transformer

In iron core transformer laminated iron core is used. This is the commonly used type of transformer.

5.3. Ferrite core transformers

Core of this type of transformer is made up of ferrite material. These transformer is used for very high frequency application.

On the basis of operating frequency

6.1. Mains frequency transformer

These transformer is basically iron core shell type transformer and connected between ac main source and other device require ac or dc power. These transformer primary have more than two terminals and secondary winding have a centre tap.

6.2. Audio frequency (AF) transformers

The size of this type of transformer is very small and it used to mounting on PCB to design to operate over the audio frequency range of 20HZ to 20 KHz.

6.3. High frequency transformers

Core of this type of transformer is made of powdered iron or ferrite material. This transformer is also called as Intermediate frequency transformers (IFTs) or Radio Frequency transformer (RFTs).

On the basis of Application

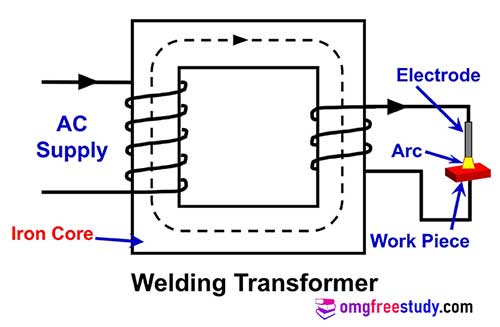

7.1. Welding transformer

In welding process large current flow through the welding electrodes so that an arc is produced between the electrodes and work piece. Hence welding transformer is a transformer having a low current in primary side and high current secondary side winding.

So the welding transformer is always step down transformer with a large number of primary turns and a small number of secondary turns.

7.2. Isolation transformer

About isolation transformer discus previously.

7.3. Constant voltage transformers

This transformer gives constant voltage at output side. It is used to obtain stabilized voltage supply for sensitive equipment’s

Transformer types based on the insulation used

8.1. Dry Type Transformer

This type of transformer does not contain any fluid cooling system, so the only cooling medium is Air only. Dry type transformers are commonly used for indoor applications where other types of transformer are considerable too risky.

8.2 Oil Immersed Transformer

In such type of transformer oil is used for cooling purposes. Using oil cooling system is better than dry type cooling. Generally this type of transformer is used for outdoor application with high ratings.

On the basis of Cooling Method

9.1. Natural cooling

In this type of transformer the cooling medium is used as a natural surrounding air to carry heat away from the transformer winding. This type of transformer rating is up to 100 KVA.

9.2. Oil filled

In this type of transformer the winding and core are immersed in oil, and radiator tubes are connected outside the tank of the transformer. Due to extra projection of radiator cooling tube the area of the tank is increased. Its rating range is above 200KVA.

9.3. Oil filled water cooled

In this type of transformer oil is used inside the tank and water is used outside the transformer tank for cooling. In it, the low pressure water is used to remove the heat from the transformer oil.

9.4. Air blast type

In this type of transformer extra fans are arranged to blow the air on the surface of the transformer thereby the heat generated is carried away by the air blast.

On the basis of Winding connection

10.1. Star-star connection

The primary winding of this type of transformer is connected in star and secondary also connected in star.

10.2. Delta-delta connection

The primary winding of this type of transformer is connected in delta and secondary also connected in delta. In delta connected winding neutral is not available.

10.3. Delta-star connections

The primary winding of this type of transformer is connected in delta and secondary is connected in star.

10.4. Star-delta connection

The primary winding of this type of transformer is connected in star and secondary is connected in delta.

10.5. Open delta or (V – V) connection

If we remove any one transformer winding of a delta- delta configuration, and a 3-phase supply is connected to the primary windings, then three equal 3-phase voltage are available at the secondary terminal as shown in the figure.

10.6. Tee-Tee or Scott connection

In this type of transformer primary is supplied by three phase and from secondary side get two phase output.